MICRO DIMENSIONS is primarily a drafting and engineering consultant to FRP

industry. Our expertise lies within the discipline of molded and pultruded FRP structures

and includes approval (structural) and shop (production) drawings of FRP (VEFR and

ISOFR) structural members that include platforms, walkways, gratings, stairs, ladders,

guard rails, weir plates, etc.

Challenges Faced By Consulting Houses

- 1. Shortage of skilled CAD professionals and engineers,

- 2. Higher operations cost per desk, higher overheads.

- 3. Turn-around time limitations.

Benefits Of Knowledge Processing Unit

- 1. Time efficient production–less turn-around time as offshore team works while clients are not due to the time difference.

- 2. Cost savings due to reduced staffing expense, less operating costs.

Frp Drafting Philosophy

- After receiving approval for an FRP quote, our clients send to us markups that their FRP estimation team had prepared as part of the bid process. Clients also send to us the list of material allocated to the project and FRP specifications to be followed.

- Micro Dimensions prepares FRP approval drawings based on clients’ markups on bid contract drawings, list of material assembly that is allocated to the project and project specifications.

- Project team at Micro Dimensions reviews the received information, assists CAD team in understanding and producing FRP approval drawings that are as per clients quote and markups and meet job specifications.

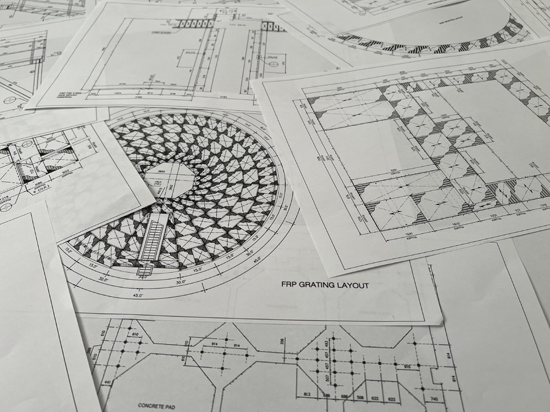

- Approval drawing set prepared by Micro Dimensions include notes, specifications, project key plans, structural layout and grating layout plans, handrail layout plan, staircase plan, location of ladders in plans, important sections and elevations, and connection details.

- Our approval drawings are then reviewed and verified by client engineer.

- Micro Dimensions team works on updates and revisions as marked by client and sends out updated/revised approval drawings.

- Micro Dimension starts working on production drawings only after receiving approval from client.

- Micro Dimensions CAD team produces shop/productions drawings based on the approved approval drawings.

- FRP shop/production drawings include approval drawings with member and grating tags.

- A detailed bill of material (BOM) that includes all FRP members, grating pieces, handrail and ladders sections, connection angles, etc. is prepared and forms the basis for detailed piece wise shop drawings of all FRP members (Beams, Columns, Braces, Stringer, etc.) and grating pieces that are square/rectangles.

- Client reviews shop/production drawings sent by Micro Dimensions, recommends revisions/changes if required, approves the received shop/production drawings package.

- Clients fabricates the whole FRP project based on the approved shop/production drawings, and ships the fabricated FRP material to job site where it is erected/installed.

Confidentiality

- We do not share any client information, data, or drawings with other existing and prospective clients.